- Euromac Punching Machine Software Free

- Punching Arcade Machine

- Euromac Punching Machine Software Update

The innovation of Euromac machines now includes their software. In fact, TopPunch® is now available in the touch screen version.

This packages maintains all the special features of TopPunch® but, as the name suggests, it runs on a 21.5″ LCD back-lit touch screen.

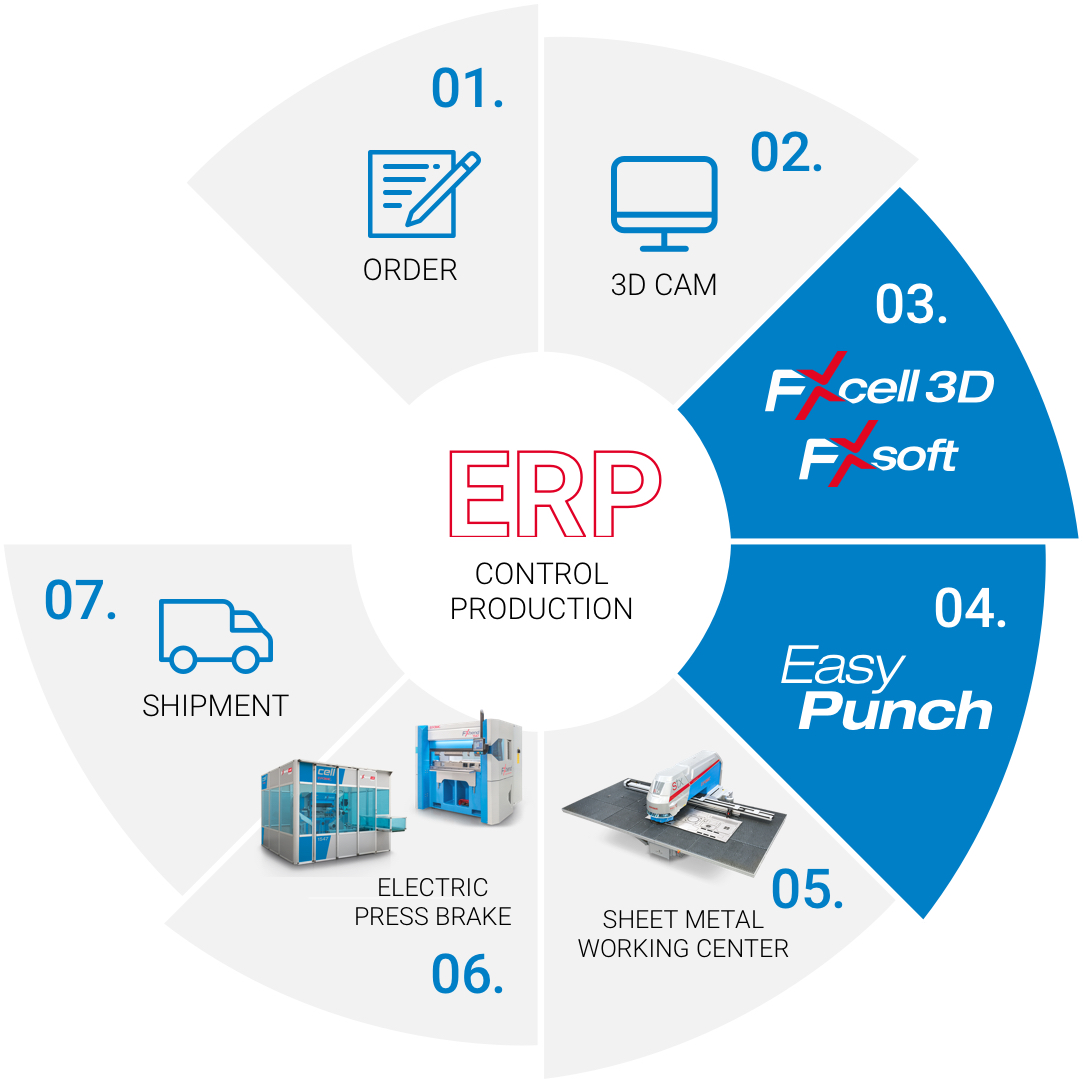

Euromac’s XT new high performance punching machine, is flexible according to any production requirement. Fully configurable, hydraulic, hybrid, electric, 6 or 12 turret machine. Working area of 3000 x 1500 mm without repositioning. Punching speed: – up to 1080 strokes per minute for nibbling 1 mm pitch. – up to 460 strokes per minute. A Striker Systems team member can discuss your specific punching software requirements and how SS-Punch can improve your productivity. Machine Independent – Supports virtually all turret punch press machine manufacturers. Automatic Punching/Sequencing – Auto punch single parts, multiple parts, or entire layouts. The Lantek software solutions are responsible for the whole process, which starts with programming the CNC Punch. During the punching process, the machine ejects/unloads the parts through a hatch. The parts then pass along a conveyer belt to an AI vision table where a camera detects the orientation of the fallen part. . All Plasma and water Jet machines are supported, ESSI code supported. ESAB; FLOW.New postprocessors: If your machine is not listed here chances are we have it, please get in contact and we will make a driver and postprocessor for your machine if we don't.

Features

- A larger and more luminous screen

- Updated and simplified layout

- Extremely sensitive Also suitable for being used wearing gloves

- Step-by-step forward and back display

- Available upon demand for the entire range of Euromac machines

- WI-FI integration

Easypunch is CAD/CAM nesting software, especially designed for automating numeric control punching machine programming.

Easypunch has an advanced, intuitive and user-friendly interface that improves efficiency during programming.

Easypunch controls autoindex tools, multitool stations and all types of tool, from the standard types to shaping, offset, boring, threading, stamping tools and many other types.

Easypunch gives you the possibility to choose between automatic and semi-automatic nesting, as well as manual, hence granting an outstanding flexibility and optimal performance. The combination of automatic and manual nesting functions (copy, shift, rotation) proves to be an extremely powerful tool.

Easypunch PLUS is an automatic nesting tool that optimises the layout of components on the sheet and offers different options for standard punching operations on regular or irregular workpieces.

Other features of Easypunch:

- Teamwork – This system can operate independently or within a network. Thanks to the floating license option, the system can be accessed by several users.

- Parameters library – The EASYPunch solution has an extensive library of parameters from which users can choose.

- Open Database – Open database where users can find components, production orders, sheets, etc. using criteria such as: material, thickness, customer, date, etc.

- Intelligent import/export function – EASY Punch can be connected to all main and currently available CAD systems (DXF, DWG, IGES, DSTV, etc.).

- Integration – EASY PUNCH works with the most commonly used 3D design systems (SolidWorks®, Autodesk Inventor®, Solid Edge®, Catia® and many others).

- Effective time and cost calculation – EASYPUNCH calculates the time and costs per workpiece and per sheet. With this information, users can draft offers, check the volume of work of each machine and print all the reports needed.

- Intelligent import/export function – EASY Punch can be connected to all main and currently available CAD systems (DXF, DWG, IGES, DSTV, etc.).

- Integration – EASY PUNCH works with the most commonly used 3D design systems (SolidWorks®, Autodesk Inventor®, Solid Edge®, Catia® and many others).

- Effective time and cost calculation – EASYPUNCH calculates the time and costs per workpiece and per sheet. With this information, users can draft offers, check the volume of work of each machine and print all the reports needed.

Innovation, reliability and productivity. If you had to define FX bend through three words would be certainly these. The Euromac range of electric press-brakes will promptly reply to your production requirements distinguishing itself for high precision and for elevated performances.

Euromac Punching Machine Software Free

Innovation, reliability and productivity. If you had to define FX Bend through three words would be certainly these.

Innovation, because the force of the press is in extension during bending with the result of having greater strength and more precision in machining.

Punching Arcade Machine

Reliability thanks to an extremely robust monoblock structure in Meehanite than any bending machine with an assembled structure.

High-level productivity with backgauges at 4 and 6-axis, fully automatic and with independent movements able to reach speeds of up to 1000 mm / sec which together with high decelerations ensure maximum productivity.

Control unit 21″

• Anti glare touch-screen LCD

• Water and dust resistant (IP65)

• Up to 9 hours battery power backup

• Windows® 10

• USB and WiFi connection

• DXF import files

• 2,5 D Graphic visualization

• 3 D Graphic visualization (optional)

- Standard configuration:

- Upper tool holder with maual clamping system and quick lever (no tools needed)

- Lower tool holder with manual clamping system and quick lever (As Optional configuration: is possible to have a lower tool holder compatible with Wila and Promecam tooling with manual crowning system).

Euromac Punching Machine Software Update

Upper and lower tool holder with automatic clamping system.

- Standard configuration:

- Upper tool holder with maual clamping system and quick lever (no tools needed)

- Lower tool holder with manual clamping system and quick lever (As Optional configuration: is possible to have a lower tool holder compatible with Wila and Promecam tooling with manual crowning system).

Upper and lower tool holder with automatic clamping system.

Fully automatic and programmable

X, R and Z1 and Z2 axes. R axis stroke 180mm

Fully automatic and independent movements

X1, X2, R1, R2 & Z1, Z2 axes.

RapidBend Ultimate eliminates slow speed altogether. The tools close in high speed until the punch reaches the material surface for the ultimate high speed performance. RapidBend technology can reduce machine cycle time by more than two seconds per cycle. This represents a significant saving in operating time and cost.

The “Active Angle Control” controls and adjusts in real time the angle throughout the bending process. The “Active Angle Control” ensures angular accuracy regardless of material variations and forming conditions as it eliminates the influence of bend length, bending force and off center loads. The result is maximum precision, absolute repeatability. No material setting, no sheet length setting, no bending force setting, no sampling test, no manual correction: you just set the desired angle and you get it, no matter which material, dimension bending force.

Fully automatic and programmable

X, R and Z1 and Z2 axes. R axis stroke 180mm

Fully automatic and independent movements

X1, X2, R1, R2 & Z1, Z2 axes.

RapidBend Ultimate eliminates slow speed altogether. The tools close in high speed until the punch reaches the material surface for the ultimate high speed performance. RapidBend technology can reduce machine cycle time by more than two seconds per cycle. This represents a significant saving in operating time and cost.

The “Active Angle Control” controls and adjusts in real time the angle throughout the bending process. The “Active Angle Control” ensures angular accuracy regardless of material variations and forming conditions as it eliminates the influence of bend length, bending force and off center loads. The result is maximum precision, absolute repeatability. No material setting, no sheet length setting, no bending force setting, no sampling test, no manual correction: you just set the desired angle and you get it, no matter which material, dimension bending force.